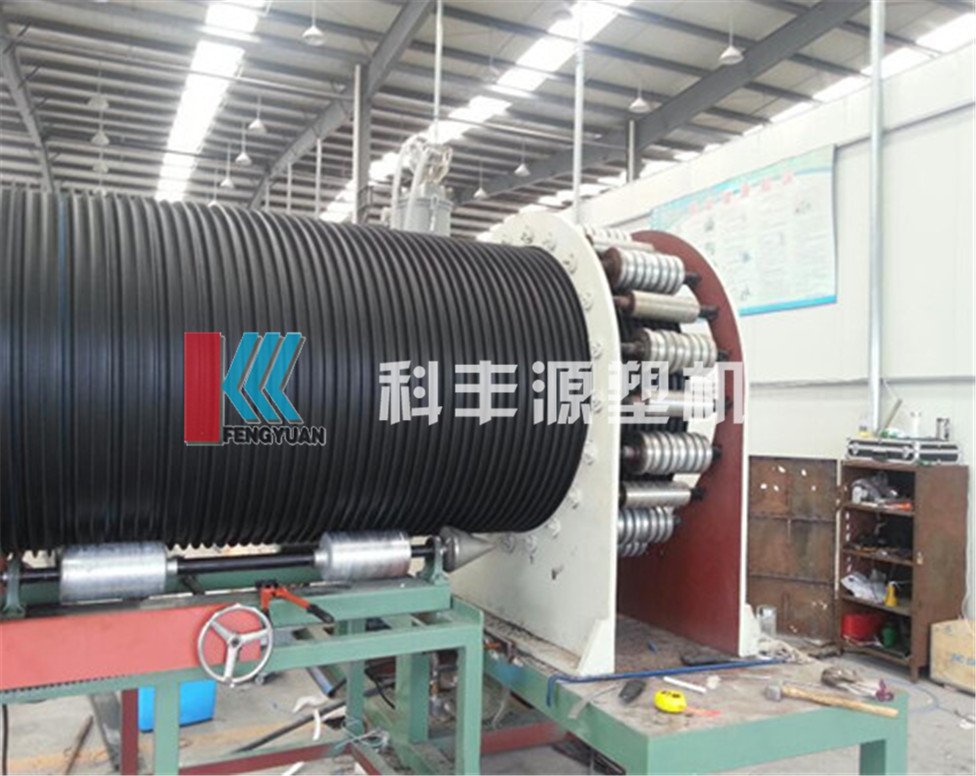

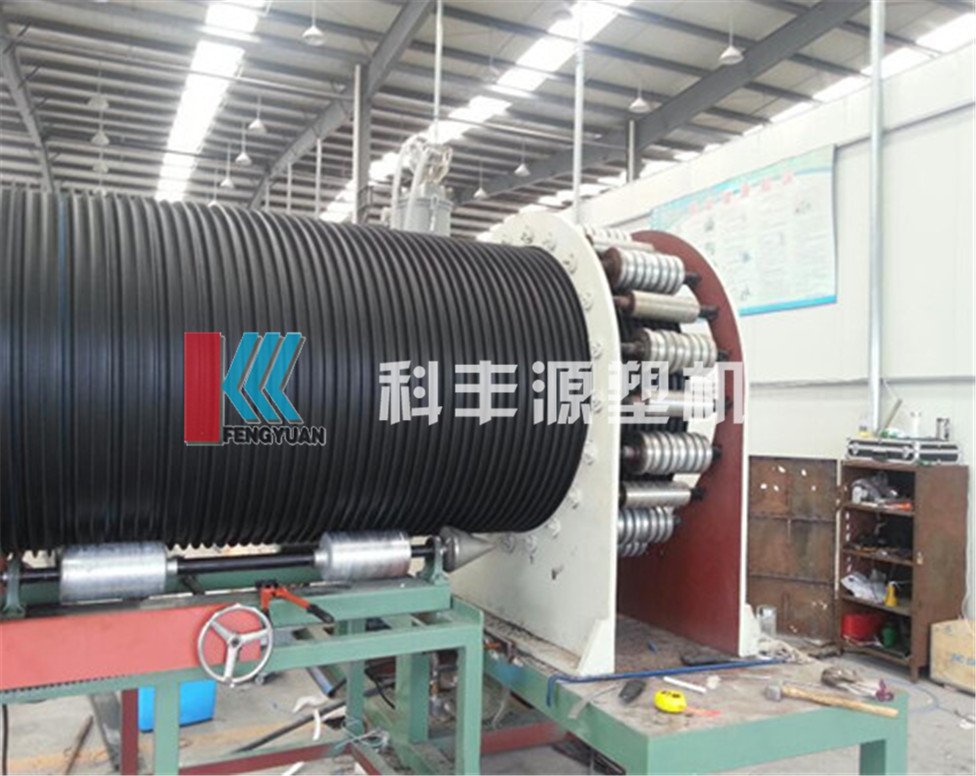

Polyethylene plastic steel winding pipe equipment to explain

Release time:2018-10-22 13:31

Wrapped polyethylene plastic steel pipe production equipment is a high-tech composite pipe product with independent intellectual property rights, world level, green environmental protection, energy saving and consumption reduction. This product is mainly used as buried drainage pipeline. It integrates the advantages of rigidity of steel strip and corrosion resistance of polyethylene, low friction resistance and wear resistance. At present, the HDPE plastic-steel winding pipe produced by the plastic-steel winding pipe production line developed by our company has been sold well at home and abroad, and is widely used in municipal engineering, sewage treatment plant and other key projects.

Characteristics of HDPE plastic steel winding pipe

1. Light weight, safe and simple, good sealing performance and low construction cost.

Because of the high stiffness-weight ratio of the plastic-steel wound pipe, its weight is lighter than that of any kind of pure plastic pipe with the same ring stiffness. Light weight, installation without large lifting equipment. Axial flexibility is good, laying on the bottom of the groove smoothness, low solidity requirements, strong ability to withstand the abnormal stress caused by improper installation. Sealed connection mode can be operated by hand with simple tools, without machinery, very simple and fast, reliable and no leakage.

2. Safe and reliable ring stiffness

Because the elastic modulus ratio of the two materials is greater than 200 and the weight ratio is greater than 7.85, the steel strip reinforcement makes the pipe (especially the large diameter pipe) have enough safe and reliable ring stiffness and relatively high stiffness-weight ratio compared with the pure plastic pipe.

3. Strong resistance to abnormal burst loading.

Because of the high stiffness and good axial flexibility of pipe rings, the pipe can be defused by elastic deformation when uneven settlement of soil, floating of groundwater, excessive local ground load, earthquake and other sudden loads and disasters occur.

The stress generated can avoid leakage or damage due to excessive stress and deformation.

4, non-toxic

Black high density polyethylene (PE) pipes are inspected and approved by relevant health departments.

5. Smooth inner surface

The smooth inner surface of polyethylene (PE) pipeline will reduce the energy loss caused by friction and it is not easy to deposit in the pipeline. The flow resistance of PE pipe is 20-30% lower than that of cement pipe. The inner wall of PE pipe is smooth, the friction coefficient is small, and the sediment is not easy to aggregate in the pipe.