Products

1. The main advantages of winding craton equipment are:

1, do not need to buy different specifications of mold - low investment costs and less space.

2, the mold does not require natural gas baking - energy saving

3, do not need to change the mold - workers save efficiency.

4, continuous production - high efficiency.

5, pipe length 1 to 17.5 meters - low transport costs

6. Socket cutting is carried out under the temperature of the party - low shrinkage and good sealing.

Two, the performance characteristics of the pull pipe produced by the carat tube equipment.

1. Excellent physical properties

HDPE has good rigidity, strength, flexibility and creep resistance, and HDPE has better hot-melt bonding properties, which is conducive to the installation of plastic pipes.

2. Corrosion resistance and long service life.

In China's coastal areas, the groundwater level is on the high side, the soil moisture is high, and PE pipe can withstand the erosion of a variety of chemical media, do not need anti-corrosion treatment. In addition, it will not promote algae, bacteria or fungi growth, with a life span of 100 years.

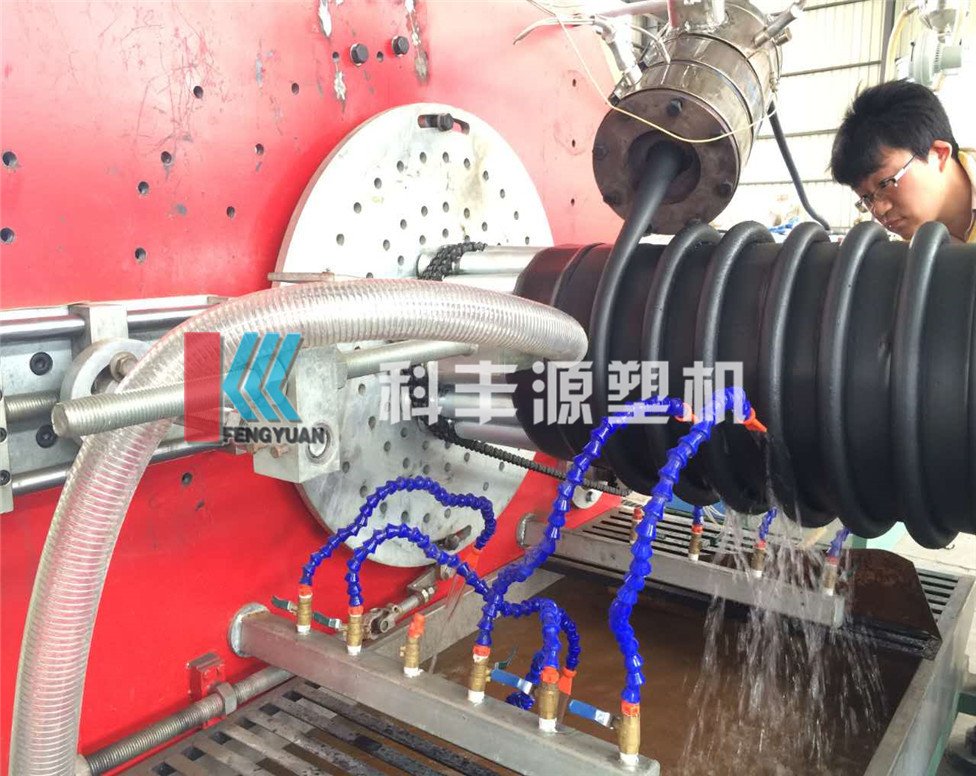

3. High quality of hot winding.

The melting flat and cladding strips extruded from the die of the extruder are evenly wound on the heated drum mold according to the predetermined position to ensure the quality of the welded joint of the structural wall pipe. The pipe is cooled by air and the material is cooled evenly. Especially in the structural design, the welding seam of the plain belt is covered by the support pipe coated by the material belt, which improves the overall anti-external pressure ability of the product. Horizontal layer of pipe and strengthening layer are welded in melting state, the weld quality is high, there is no internal stress, and the overall strength of pipe is high.

4, ring flexibility

Plastic pipes belong to flexible pipes. Under external pressure, flexible pipes and rigid pipes bear different load mechanisms. Flexible pipe can deform greatly before it is destroyed by compression, while rigid pipe can not deform greatly before it is destroyed by external pressure. When the rigid pipe is subjected to external pressure, the load is transmitted completely through the pipe wall to the bottom of the pipe bed, and the bending moment is generated in the pipe wall. With the increase of pipe diameter, the bending moment and stress of the pipe wall increase sharply, so the large diameter concrete drainage pipe often needs reinforcement: while the flexible pipe deformation-lateral expansion before compression failure, pipe material. The surrounding backfill soil can prevent the deformation and expansion of flexible pipe, and the external pressure load is transferred and distributed to the surrounding backfill soil. Therefore, under the same external pressure load, the stress in the flexible pipe wall is smaller, it and the surrounding backfill bear the load, pipe and soil interaction. Therefore, the plastic buried drainage pipe does not need the same strength and stiffness as the rigid concrete pipe, under a reasonable stiffness, it can completely meet the requirements of use, which has been proved by the practice of European developed countries.

5. Toughness and flexibility.

PE pipe is a kind of high toughness pipe, its elongation at break is more than 500%. It has strong adaptability to uneven settlement and dislocation of pipe foundation, and has good seismic resistance. Therefore, PE pipe is most suitable for seismic risk areas. Practice around the world has proved that PE pipe is the best seismic resistance pipeline. It is reported that PE pipes and water supply pipes are the only pipelines that have not been damaged in the 1995 Kobe earthquake in Japan. In addition, the flexibility of PE pipe is that PE pipe can be coiled (especially small PE pipe diameter), reducing a large number of connection pipe fittings. The direction of PE pipe is easy to change according to the requirements of construction method. During construction, it is possible to bypass obstacles in the allowable bending radius of the pipe and reduce the difficulty of construction.

Top